Thermal bridges

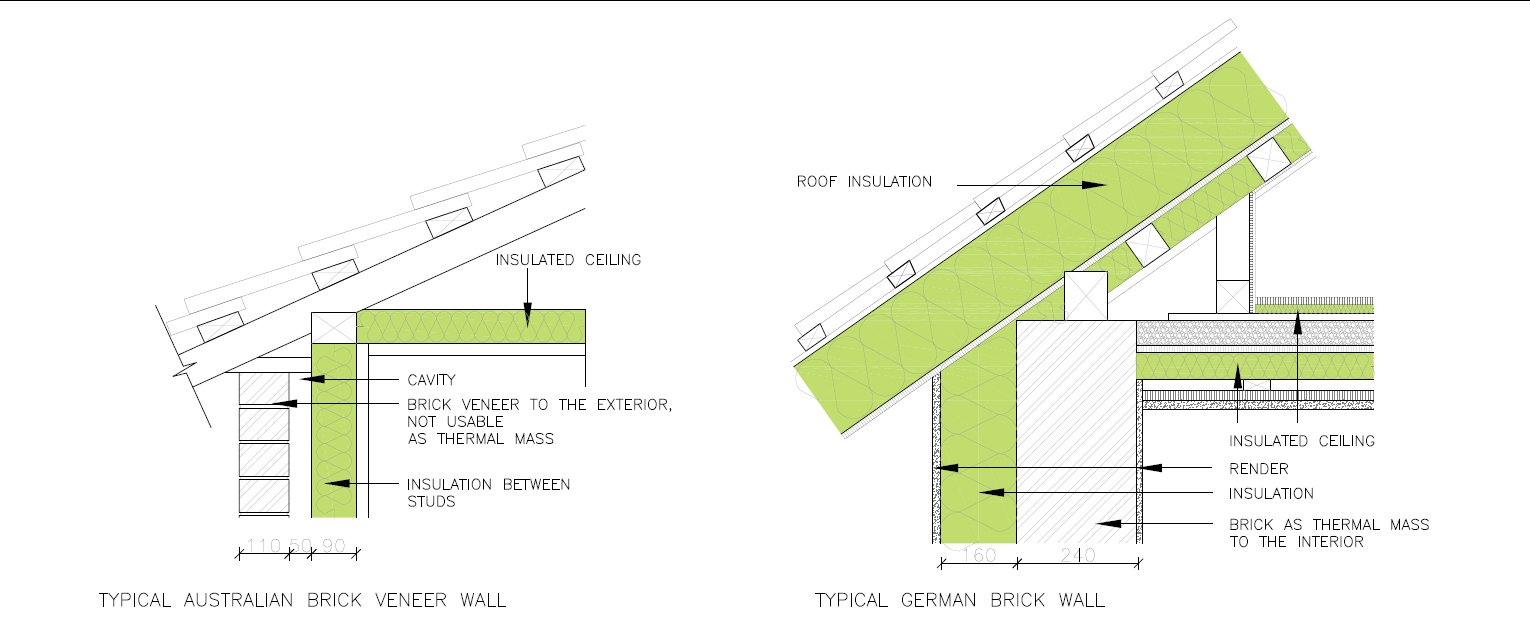

When I started working in Australia in 2007, I was puzzled how thin walls can be. For example, an external wall can be 110 mm, 90 mm for the timber studs, 10 mm plasterboard on one side, 10 mm FC sheeting on the outside and insulation just between the studs. This construction, in general, is not allowed in most European countries, as it creates a structural thermal bridge. The U-value of timber is much higher than the U-value of the insulation, which means that heat can escape through the timber studs in the wall and consequently increases unwanted heat gain or loss. In Europe, the main focus lies on avoiding thermal bridges. Timber construction is usually done as a double stud wall. In this case, there is also a timber stud to the interior, covered with plasterboard and insulation between the studs, but at the outside is another continuous layer of insulation, and then another timber stud, with external plasterboard and again insulation in between. (see diagram below)

In Australia, there are no strict regulations about thermal bridges and also no minimum insulation regulations for concrete slab-on-ground construction, roof or internal walls.

Example of insulation for a typical Australian home compared to a German home

| AUSTRALIA (Melbourne 2015) | GERMANY (2010) | |

| External Wall | R-value: 2.8 | R-value: 5.0 |

| Roof | Not required | R-value: 6.6 |

| Ceiling | R-value: 4.1 | R-value: 3.3 |

| Internal Walls (to garage, bathroom, staircase etc.) | Not required | R-value: 3.3 |

| Floor |

R-value: NIL for slab on ground R-value: 2.25 for a suspended floor |

R-value: 3.3 |

Obviously, the average temperature in Germany is much lower than in Australia, therefore it is natural, that the R-values of the insulation need to be higher, but there are also some differences in where the insulation needs to be installed. In Australia, usually just the ceiling gets insulated, although the roof space is ventilated, heat can be trapped inside in summer which can transfer through the ceiling and heat up the rooms below. In Germany, the main focus lies on the roof itself, the whole outside of the building is treated as a continuous shell. Ideally, no heat should be able to transfer into the building at all. There are no wall or roof vents, most of the buildings are even air-tight.

For instance, in winter you can easily distinguish between a good and a bad insulated home in Germany. In a good insulated home, snow won’t melt on the roof tiles, as no internal heat can escape the through the insulation which reduces the energy required for heating enormously. Furthermore, it is also a requirement to insulate the ceiling to roof space and floors to ceilings between different levels, as well as to place insulation on some internal walls, for instance, walls between rooms with different heating requirements, to unheated corridors, garages etc. This is to stop heat ‘traveling’ through a house from room to room.

Furthermore, typical brick veneer constructions, as shown above, are not advisable, as the thermal mass is located on the outside of the building and therefore can’t be used to actively contribute to heating and cooling needs. Brick should be located on the inside. Therefore a better opting would be to use a reverse-brick construction, where the brick is inside the building envelope and consequently is able to store heat and to regulate the indoor temperature.

What can we learn from overseas?

Minimising thermal bridges and heat transfer is mandatory in order to create energy efficient and environmentally friendly buildings. All insulation must be installed snug-fit, there should be no gaps and also thermal bridges should be avoided where possible in order to minimise greenhouse gas emission and to protect the environment.